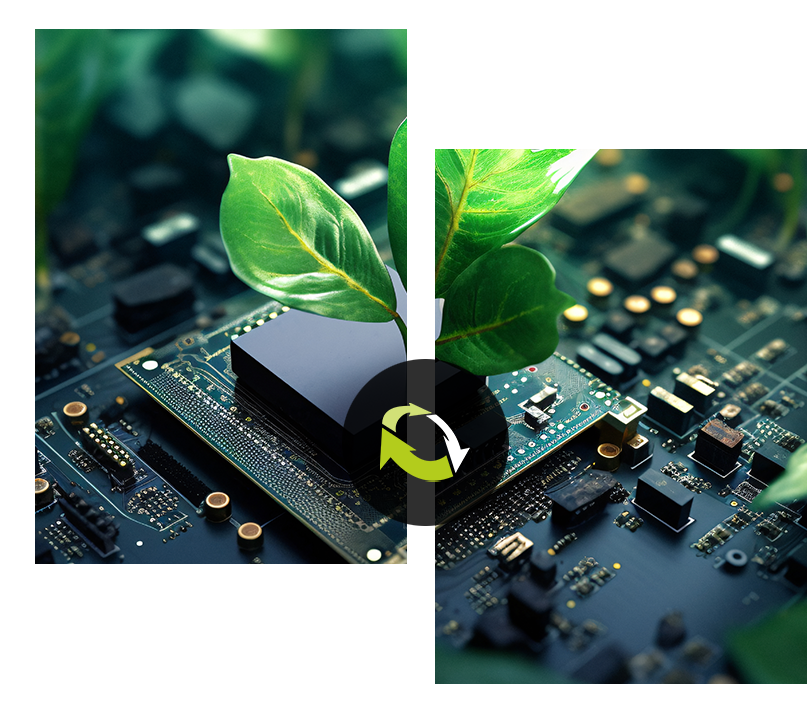

PCB RECYCLING

Leader in the recycling of integrated printed circuit boards

We are the European leader

in the professional preparation of electronic waste for the recovery of copper and precious metals from printed circuit boards and devices containing PCBs

Our offer

MB Recycling, as an innovative leader in its sector [photos for individual groups in the list below], specialises in recycling of the following assortments:

Printed circuit boards

all grades and types

Copper and gold laminates

Components from electronic devices such as:

• hard disks • CD/DVD drives • power supplies

Entire electronic devices such as:

• Laptops • PCs • Servers • Routers • Switches • Tablets • Telephones

Operationally, we are capable of processing all electrical and electronic waste.

Comprehensive services:

Competitive prices

Specialised transport

Competitive payment methods

Fast and professional service from a dedicated account manager

Safe recycling

Recycling Lab

We focus on high quality

continuous development and long-term partnerships

Contact US

Grzegorz Bartuś

PCB/WEEE/E-scrap development director

Dawid Stępień

Germany, Austria, Greece,

North Macedonia, Italy, England, Turkey

Maciej Bryk

Poland, Finland, Croatia, Slovakia, Bosnia and Herzegovina, Albania, Kosovo,

Czech Republic, Lithuania, Latvia, Estonia, Denmark, Sweden, Norway

Jakub Gusta

Netherlands, Romania, France, Spain, Portugal, Slovenia, Belgium, Bulgaria

Irina Shcherbatiuk

Bulgaria, Italy, Serbia, Finland, Sweden, Bosnia and Herzegovina, France, Norway, Georgia, Kazakhstan, Uzbekistan

Do you have additional questions? Are you interested in cooperation?

Fill in the contact form!

Our specialist will contact you in max. 24 hours!

About us

We use the latest technology

in the professional preparation of electronic waste for the recovery of copper and precious metals from printed circuit boards and devices containing PCBs

PCB recycling

Feeding the load to an inspection conveyor, after which the fraction is directed to a shredder with hydraulic pressure.

1.

Individually calibrated shredder, which shreds the tiles and the entire machine to the required fraction (usually 34 mm) The pressure force and speed are adjusted automatically.

2.

Separation by means of an oscillating sieve and fine screening.

3.

Feeding the load to an inspection conveyor, after which the fraction is directed to a shredder with hydraulic pressure.

4.

Second stage magnetic separation with higher power.

5.

Optical separation.

6.

High-sensitivity optical/inductive separation to separate the flow into two fractions: plastics and wafers.

7.

The entire process is controlled by an integrated control system.

8.

Why is the recycling of Printed Circuit Boards (PCBs) important?

Environmental protection:

PCBs often contain toxic substances, such as lead and cadmium, which can contaminate soil and groundwater, with negative impacts on ecosystems and human health. Recycling avoids depositing these hazardous materials in unsuitable landfills.

Raw material savings:

Energy reduction:

Reduced generation of electronic waste:

Recovery of precious metals:

Operating in compliance with regulations:

We have our own extensive vehicle fleet

Our plants